Medicine And Technology: Hand-In-Hand

While the best methods of maintaining healthiness are the oldest ones—eating right and exercising properly—today’s technological environment makes it possible to address a wider range of maladies previously thought incurable. The gap between sicknesses thought incurable and new treatments are lessening every day, and the tech sector is one reason why.

When it comes to the modern healthcare industry, technological solutions hailing from the IT sector have proved increasingly fundamental to forward developments. Cloud computing (and associated applications), as well as the Internet of Things (IoT), are especially conducive in these areas, but they are by no means the total measure of technological innovation in medicine.

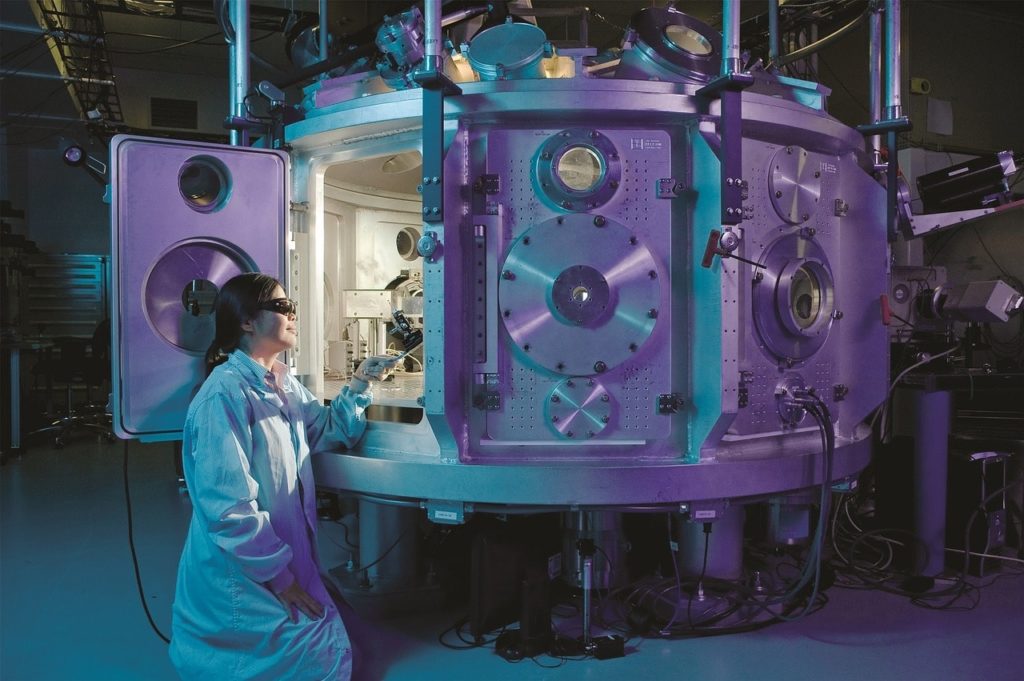

There are several popular prototyping techniques out there which provide for the rapid development of new technology conducive to medical environments. As new breakthroughs are made in the understanding of human biological systems, new devices to help address issues that couldn’t be dealt with previously manifest. Several will be explored here—such as CNC machining.

A Variety Of Different Prototyping Solutions

If you’re unfamiliar, CNC machining refers to a kind of “subtractive” means of prototyping. Quickly-designed, exceptionally accurate and functional prototyping solutions often result. This option can save money and account for geometrical patterns that are complex. Additionally, many different materials can be used, including thermoplastics as well as metallic substances.

One source of metal stamping is Weiss Aug because even the smallest parts need precision. Several other means of prototyping that have become increasingly popular today include aluminum machining, Reaction Injection Molding (RIM), and Vacuum Casting. Each of these prototyping methods will have different advantages and disadvantages depending on the kind of prototypes that are being produced.

Determining Which Type Of Prototyping Is Best

When you can determine the best kind of prototyping for your needs beforehand, you’re going to save both time and money. A few factors are worth considering as you go about determining what kind of machining will best match development needs.

Firstly, you want to ensure that the concept you have in mind will actually work. In engineering, this is called “proof-of-concept”. Once you have the proof of your concept determined, you’ll want to consider what function the post-prototype will serve within a given healthcare facility.

Prototyping something like an MRI will usually require larger prototyping solutions than prototyping something akin to an EKG. The materials used will be defined in the proof-of-concept stage, and will additionally recommend one kind of prototyping over another.

After you have your new prototype made, next its functionality must be tested, the appearance, effectiveness, and “fit” of the new device must be tested, regulatory requirements must be explored, and the effectiveness of the machine over its life cycle must also be considered.

Prototyping Solutions Are More Qualitative Than Ever

For all these things, a long period of design, production, and testing are recommendable; however, there are almost certainly going to be those who wait on prototype effectiveness with their very lives at stake, predicating expedient development. The faster a prototype can be printed and tested, the better.

While haste makes waste, as the popular saying goes, today’s technological environment makes it possible to increase the speed of innovation without sacrificing quality.

Multiple data points make this possible, as do technological solutions designed to handle increasingly large quotients of data in ways that have expanded viability. The gap between concept and concept realization grows smaller every day, and prototyping like that outlined in this writing is a big reason for this shift.